Frequently Asked Questions for Swamp Coolers

Swamp cooler is great. This essential application ability to ventilate large open spaces, even in humid environments, spot cooling and just cooling in genera. Swamp cooler provides an economical and energy efficient solution to keeping home or workplace comfortable.

If you want air cooler, then you’ll love this guide. you can filter through the frequently asked questions list to find the best answer for you.

1. How does swamp cooler work?

Water is pumped from a reservoir to wet the cooling pad. After that, a blower or a fan draws warm air from outside and passes it through the damp pad. As the warm air passes through the wet pad, it is cooled through evaporation before being let out into the air.

2. How much does the air cooler lower the temperature?

The temperature of the air coming out of the equipment depends on the temperature and humidity of the air going in. Also, the constant movement of the air that is created by the blower makes the air released feel 3 to 5-degrees cooler than the actual temperature.

3. How much water does an air cooler use?

The amount of water your cooler uses depends on three primary factors:

1) Size of the unit:

Generally, the smaller the unit, the less water it will consume. For instance, a system that is under 100 watts or 500 CFM averages less than 4 liters per hour. On the other hand, a bigger unit may use as much as 20 gallons.

2) The combination of heat and humidity:

On a dry day, the system will use more water and provide added cooling when compared to a humid day.

3) How the drain valves are used:

A drain valve allows recycled water to be drained out, and in its place, fresh water is used. Draining the recycled water from the cooler is essential as it prevents the accumulation of mineral deposits in the water that tends to cause damage and corrosion. However, you should know that a continuous drain may result in 50% more water use. When drained intermittently, additional water use can be reduced to about 10%.

4. Where are swamp coolers applicable?

– Factory cooling: This equipment can be used in a single or multiple areas and is recommended for factories that need a lot of cooling and ventilation.

– Warehouse cooling: This system works well even in areas with open roller doors to provide ventilation and a cool working place.

– Shop/retail cooling: It provides an efficient and economical way to cool retail premises

– Restaurant cooling: One of the most important aspects of creating a conducive environment not only for workers but also customers in a hotel is through the cool fresh air and comfortable temperatures.

– Office cooling: An industrial air cooler can be used in open-plan offices or those with a more sophisticated setting.

– School cooling: The equipment offers an economical and effective way of cooling for learning institutions.

– Workshop cooling: This system is exceptionally affordable to install and run. It also works fast and efficiently.

5. How many types of swamp water coolers are available?

There are two main types of evaporative air cooler:

1) The Portable Air Cooler

This cooler can be run from anywhere whether it is from factory building or outdoor work sites. The portable cooler is highly recommended for mobile workers who keep moving from one location to another and those whose health may be compromised by high temperatures.

2) The Installed Air Cooler

These coolers have outstandingly large intake ducts that allow maximum airflow volume. They pump out approximately 7,700 cubic feet of air every minute for adequate cooling. However, the range of an installed cooler depends on the direction of air. For instance;

A wall or window-mounted air cooler is capable of cooling an entire room, house or garage way.

An evaporative air cooler mounted in the roof releases cold air downwards directly into the target area. It is adequate for cooling an entire home.

The side-discharge can be mounted on the side of a building or the roof. This air cooler uses an elbow to beat the wind into a current through an opening at the top or side. It can also be used to cool an entire house.

6. What makes the installed cooler more effective than the mobile cooler?

There are many advantages of using an installed evaporative cooler as opposed to a mobile cooler. This is because the air temperatures inside an industrial building tend to be higher than the outdoor temperature.

1) The building’s outer fabric picks up the suns radiant heat and transfers it to the air inside. The heat generated by the industrial equipment tends to add up to the temperatures inside the building. Hence, a mobile air cooler will need to cool the air from much higher starting level, which tends to pull its efficiency back. For instance, if the temperature outside is 29C and the air inside is 39C, it means that the mobile air cooler will need to work harder to readjust to the high temperatures. Conversely, the installed evaporative cooling system does far less work as it does not need to regulate but start cooling from the 29C to achieve the same effect.

2) Secondly, the installed evaporative cooling system supplies the cooled air directly to the occupied level. This lifts the warm air created by the equipment and pushes it out through the vents in the roof. The warm and cool air does not mix, nor does it impact the workers. Unlike the installed air cooler, the mobile cooler mixes the cool air it produces with the air surrounding it.

3) Other benefits of the installed evaporative cooler include purification. The air produced by the equipment, even without further filtration is clean. This is because any airborne dust it contains will be trapped in the wet pad as it comes through the cooler. Also, due to the addition of ductwork, you can fit ancillary filtration and inline heating.

7. What determines the size of a swamp cooler my plant needs?

Evaporative coolers are rated by the cube meter per hour (CMH) of air it can blow. There is a simple formula used to determine the proper size of air cooler you will need.

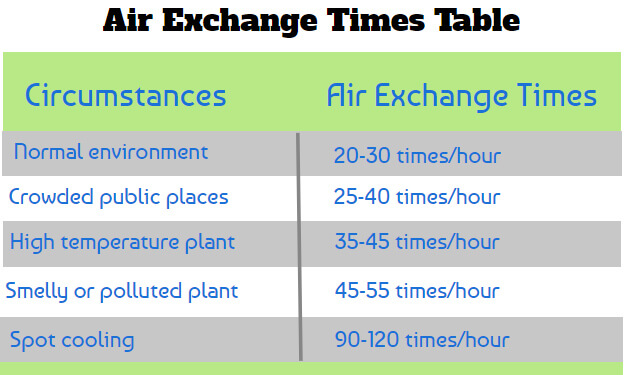

CMH OF AIRFLOW NEEDED = SQUARE METER AREA X CEILING HEIGHT X AIR EXCHANGE TIMES

P.S.: Air Exchange Times Required Under Different Circumstances

8. Is an installed evaporative cooler better than AC unit?

When operating a huge industrial plant, traditional air cooling methods can be expensive or ineffective at fighting extremely high temperatures. However, industrial air coolers come with fitted water tanks or hose attachments that affordably allow for recycling.

1) Air coolers work in open areas

Other than being cost-effective, swamp coolers produce 100% fresh air. They also don’t recirculate the same air like the air conditioner. This fresh air helps to increase productivity, promote the feeling of well-being and sustains higher and better concentration levels.

2) Affordable running costs for an Air Cooler

Although the installation of an evaporative cooler is more expensive than an air conditioning unit, it provides a feasible cooling solution for the most industrial buildings. This helps to complement inherent openness. The cost of running this equipment is minimal due the low-pressure drop of the fan and the small pump that circulates the water. In fact, these expenses are a fraction of what it would cost to run an air conditioning based equivalent system.

9. Does the evaporative cooler pose any risks to your health?

Although there have been rumors about the industrial cooler system causing legionella, there are no recorded cases to prove it. According to research, transmission of this virus is not possible through the evaporative method. The industrial evaporative air coolers only cool the air close or less than its wet bulb temperature. Hence, its water rarely rises above 20C, which is outside Legionella risk range. Additionally, the water in the cooler is not stagnant as it keeps on getting drained from the unit.

10. How to maintain the water air cooler quality?

Here are a few simple steps you should follow to maintain the quality of your air cooler:

Before summer:

– disconnect your unit from the power

– Remove all the external weatherproof covers

– Remove the filter pads and thoroughly clean them with a hose. If necessary, replace with new filters

– Close all drains and fill your unit with clean water

– Use biocide to disinfect your unit. Avoid chlorine-based household bleach and other substances that promote the growth of harmful organisms

At the end of summer:

– Disconnect your unit from the electrical power

– Take the time to loosen any slime and sediment with a brush

– Drain all the water from the tank and pipes

– Use a clean cloth soaked in chlorine-based household bleach to clean the tank. Pump and then flush it with fresh water.

– Remove the filter pads and the hose and allow it to dry

– Dry all the internal components and leave the drains open

– If necessary, fit the covers on all exposed units to prevent damage

11. What Air Cooler models are available?

– Portable air cooler

– Ducting air cooler

– Window air cooler